Gearbox Design Project

This project was for my CAD and machine components class. Our task was to design a gearbox from start to finish. We were required to supply all technical drawings and documentation for our design, determine reasonable tolerances for all custom parts and fits, and to calculate the life for all bearings as well as the gearbox overall. I was the team leader for this project.

Introduction

The final project for my CAD and machine components class was to design a gearbox. There were not a lot of given technical constraints, so there were a lot of choices regarding the design. This allowed students to exercise their teamwork and leadership abilities to make good design decisions.

Design

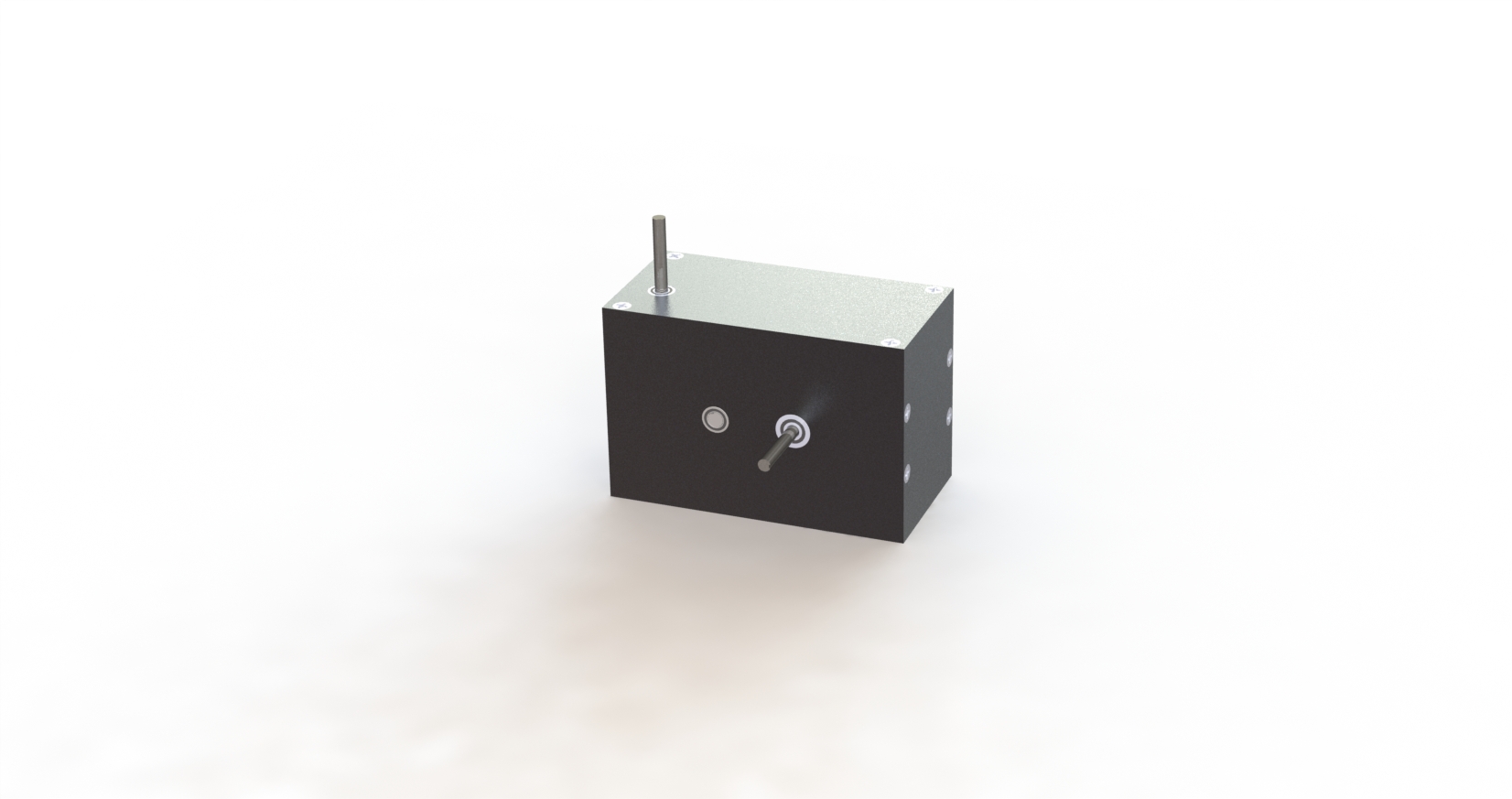

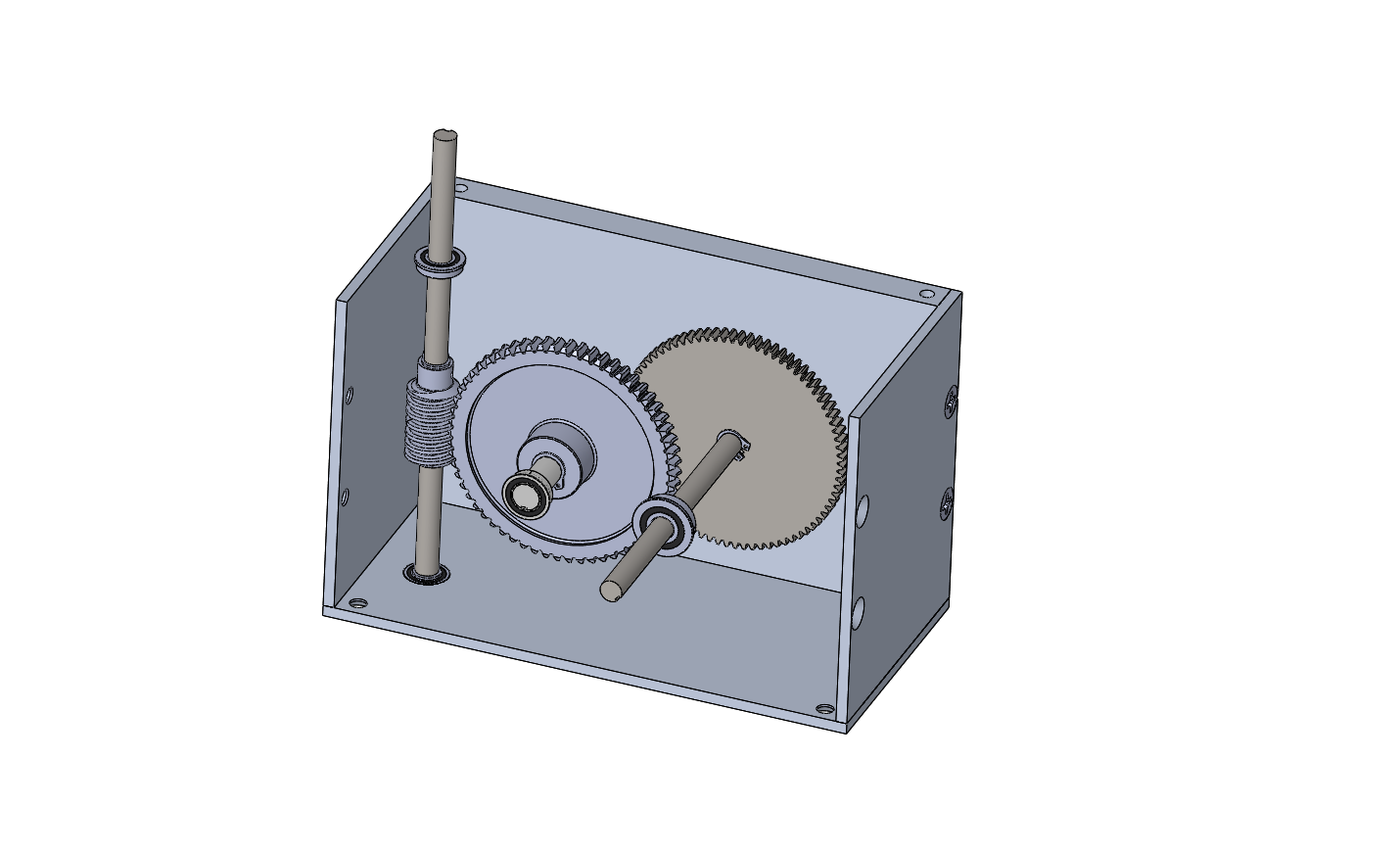

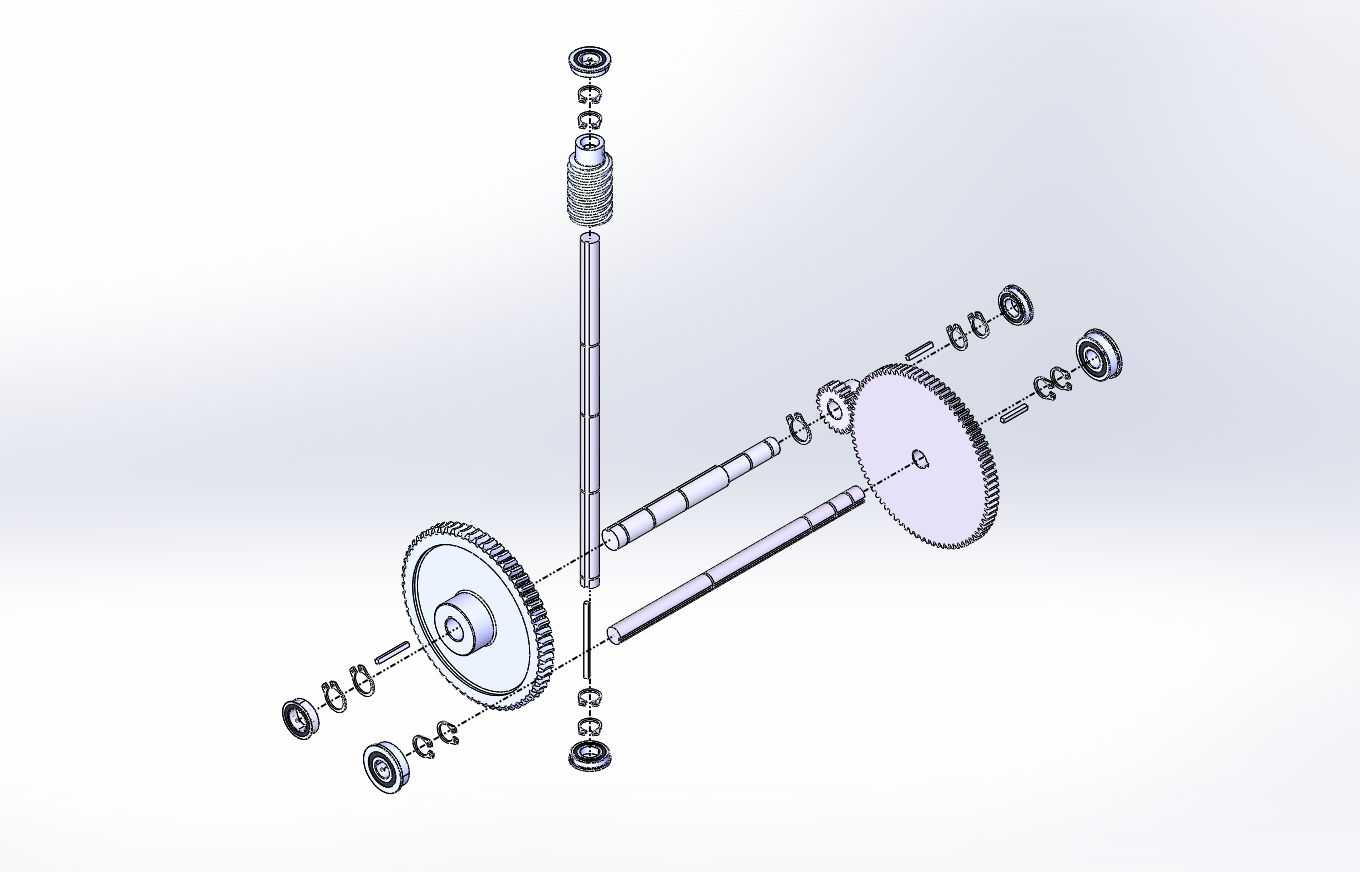

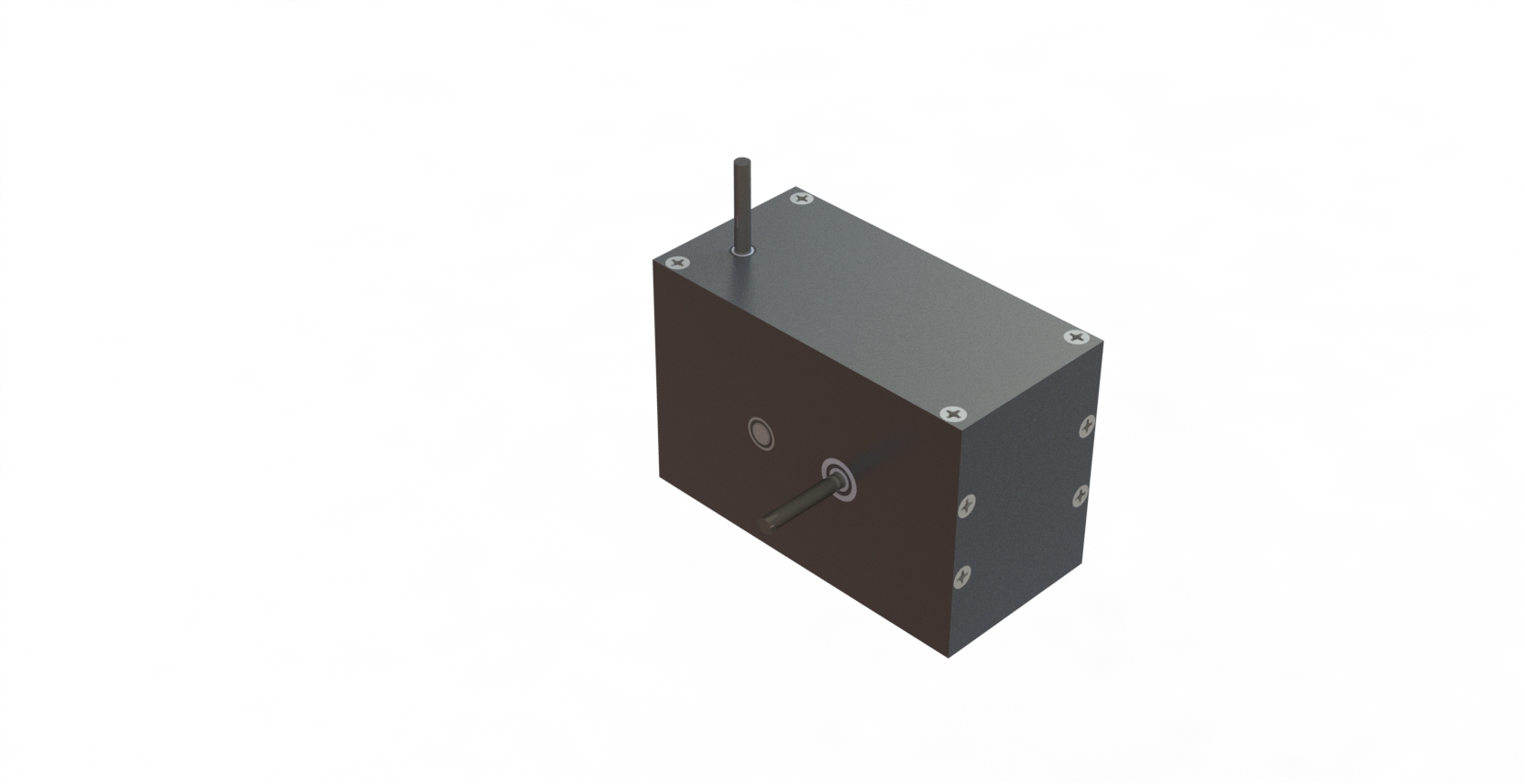

Some of the design requirements were for the gearbox to have a 240:1 gear ratio and a 90 degree angle between the input and output shafts. Our design used four gears (one worm, one worm gear, and two spur gears) to achieve these requirements. We decided to use keys for torque transfer and retaining rings for axial component retention. The gearbox housing is made of plate aluminum and is assembled with countersunk machine screws. In future versions I would redesign the housing by making the base and two sides one machined part. This would allow for looser tolerances in the holes required for shaft alignment.

Analysis

I performed numerous tolerance calculations to ensure the proper fit of all parts and sub-assemblies. The load and life of all bearings was calculated to assure that all bearings met the 25,000 hour life requirement. Finally, I made drawings of all the parts and assemblies and wrote a report summarizing our design choices and calculations.

Conclusion

Aside from all the technical knowledge I gained from this project, I also learned a lot about leadership and working in a team working on this project. In my opinion, the most difficult part of the project was navigating the design process and working as a team to make decisions. Performing the calculations and making the drawings was straightforward once the design was finalized and all the components were chosen and the design was decided.