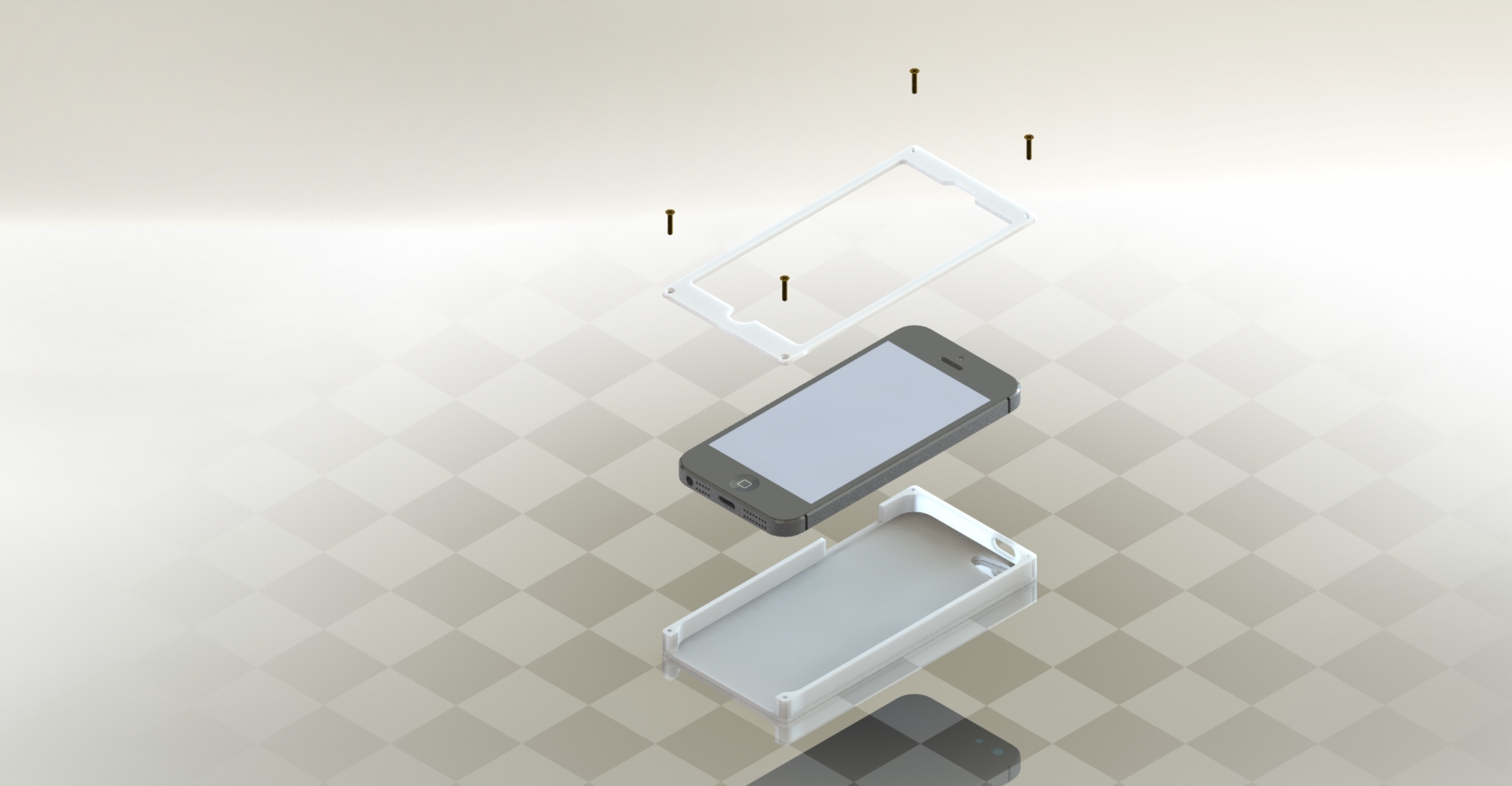

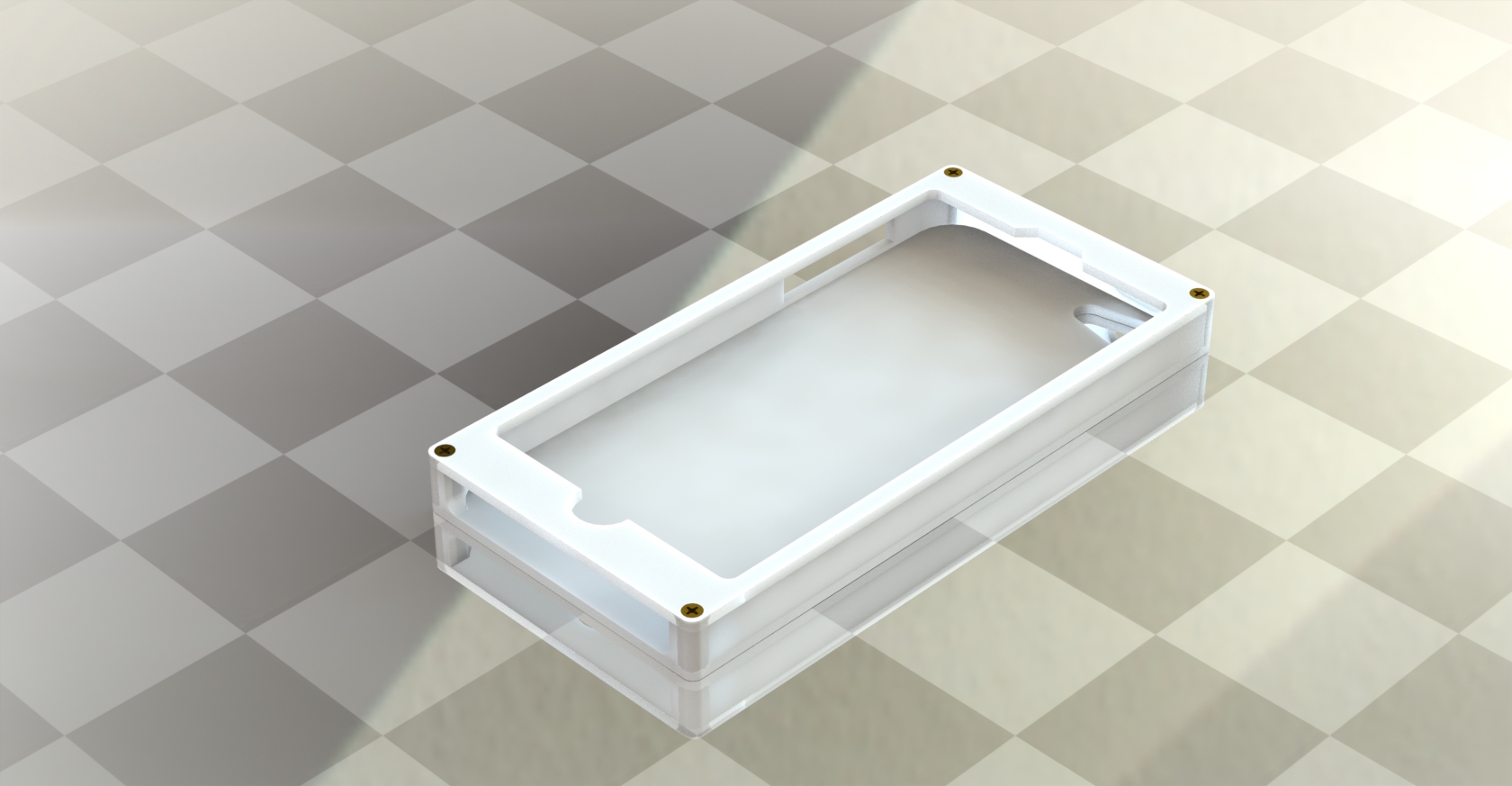

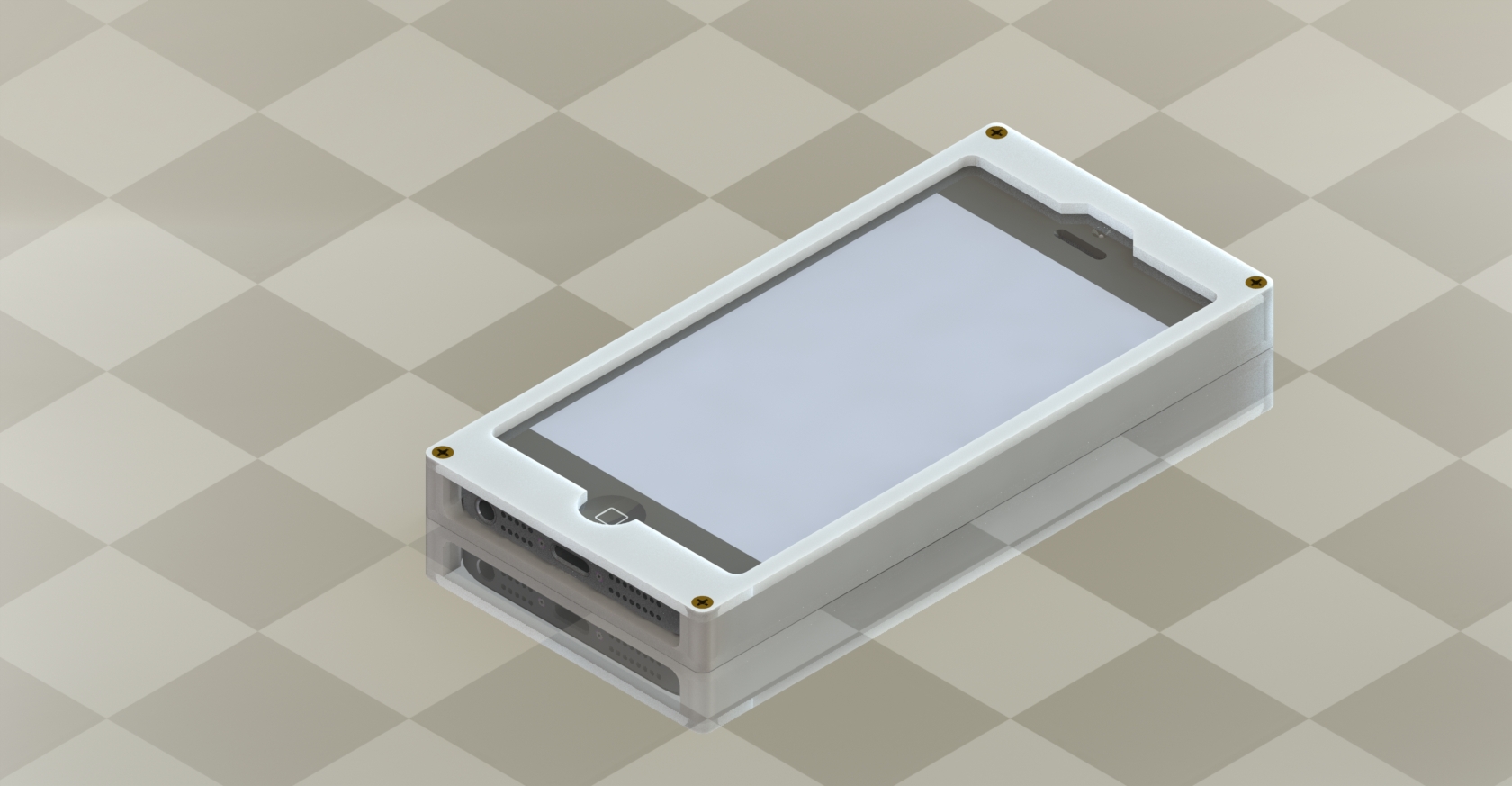

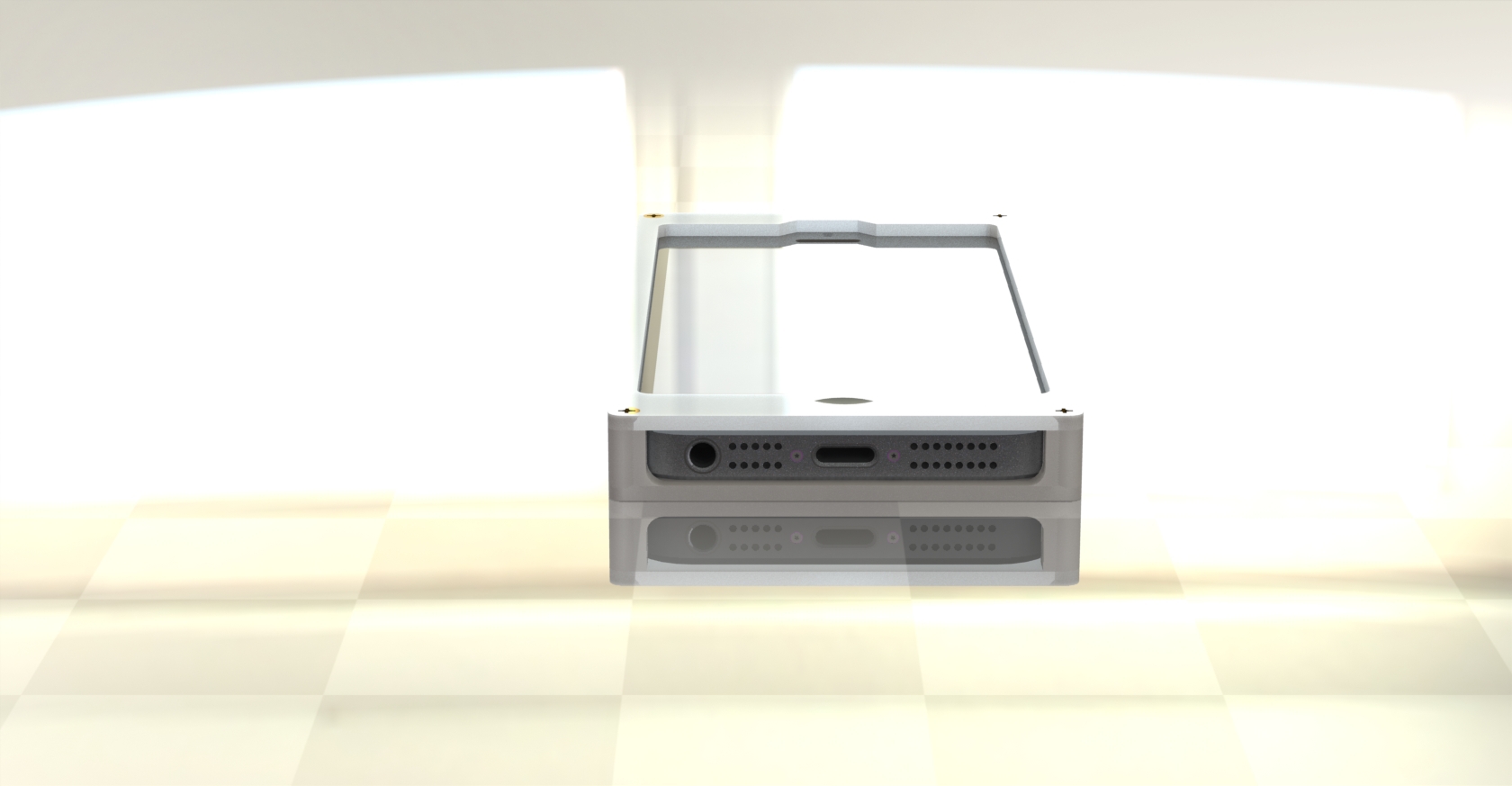

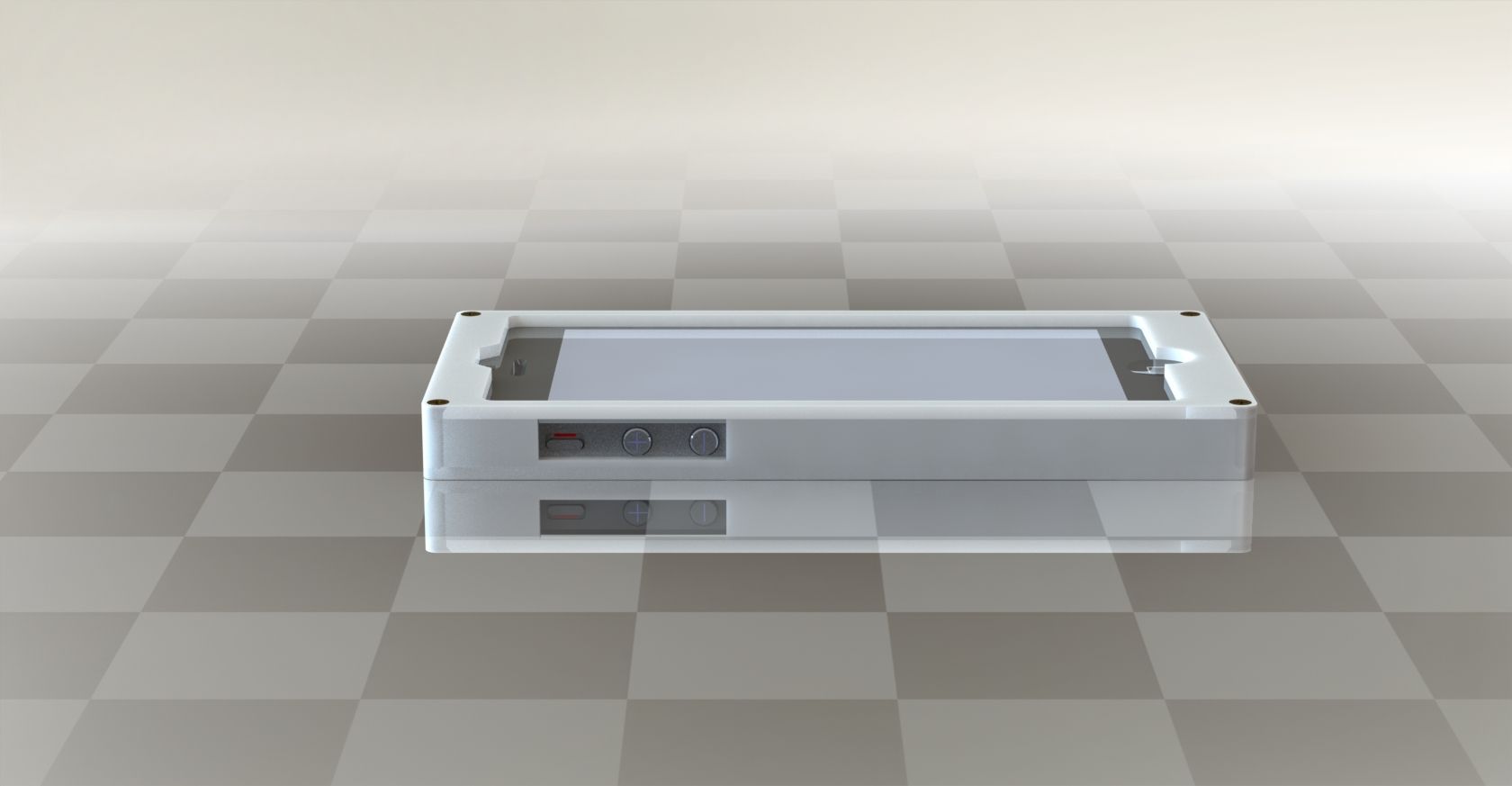

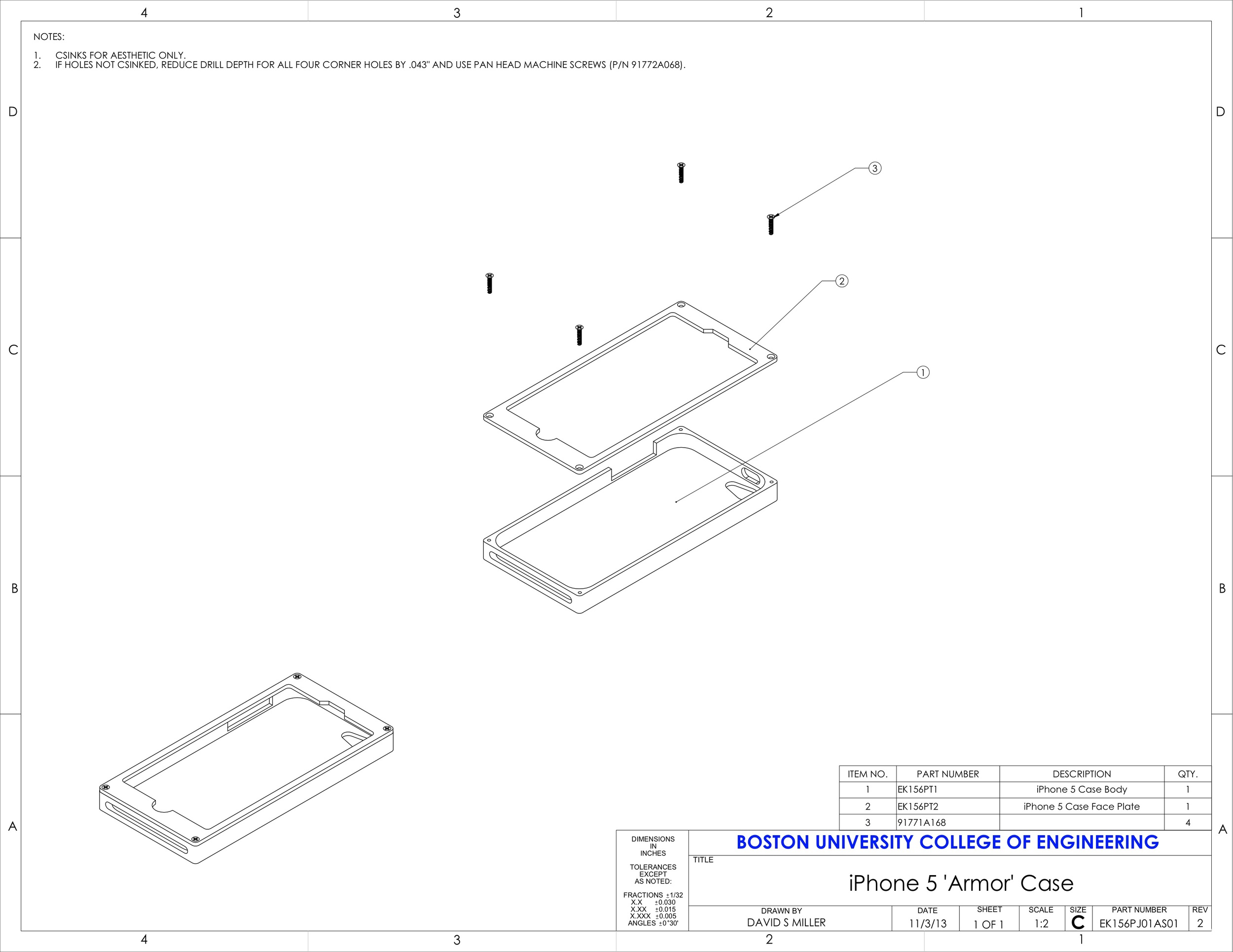

iPhone 5s Case

This was my first engineering project at BU, for my Mechanical Design and Manufacturing class. The goal of the project was to design and manufacture a product of our choice. We decided to do something simple - an iPhone case. It was useful, and because we didn't have to pay for machining time, it ended up being cheaper than buying a case! I was team leader for this project.

Introduction

In my second year at Boston University, I took a class that focused on the completion of a simple project from conception all the way to manufacture and assembly. Because this was an introductory class and most of us had very little relevant coursework at the time, most projects ended up being simple toys or games made from plastics.

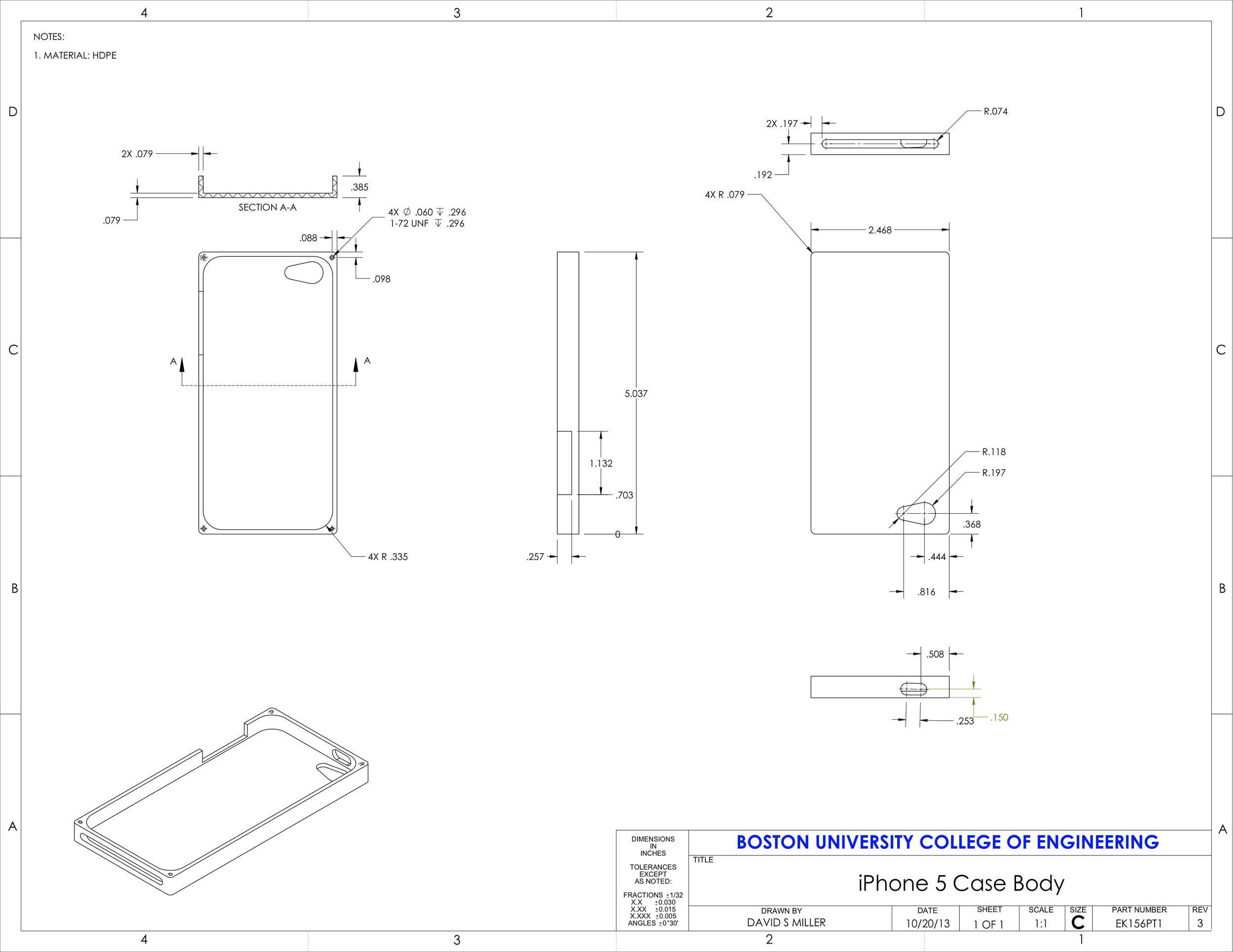

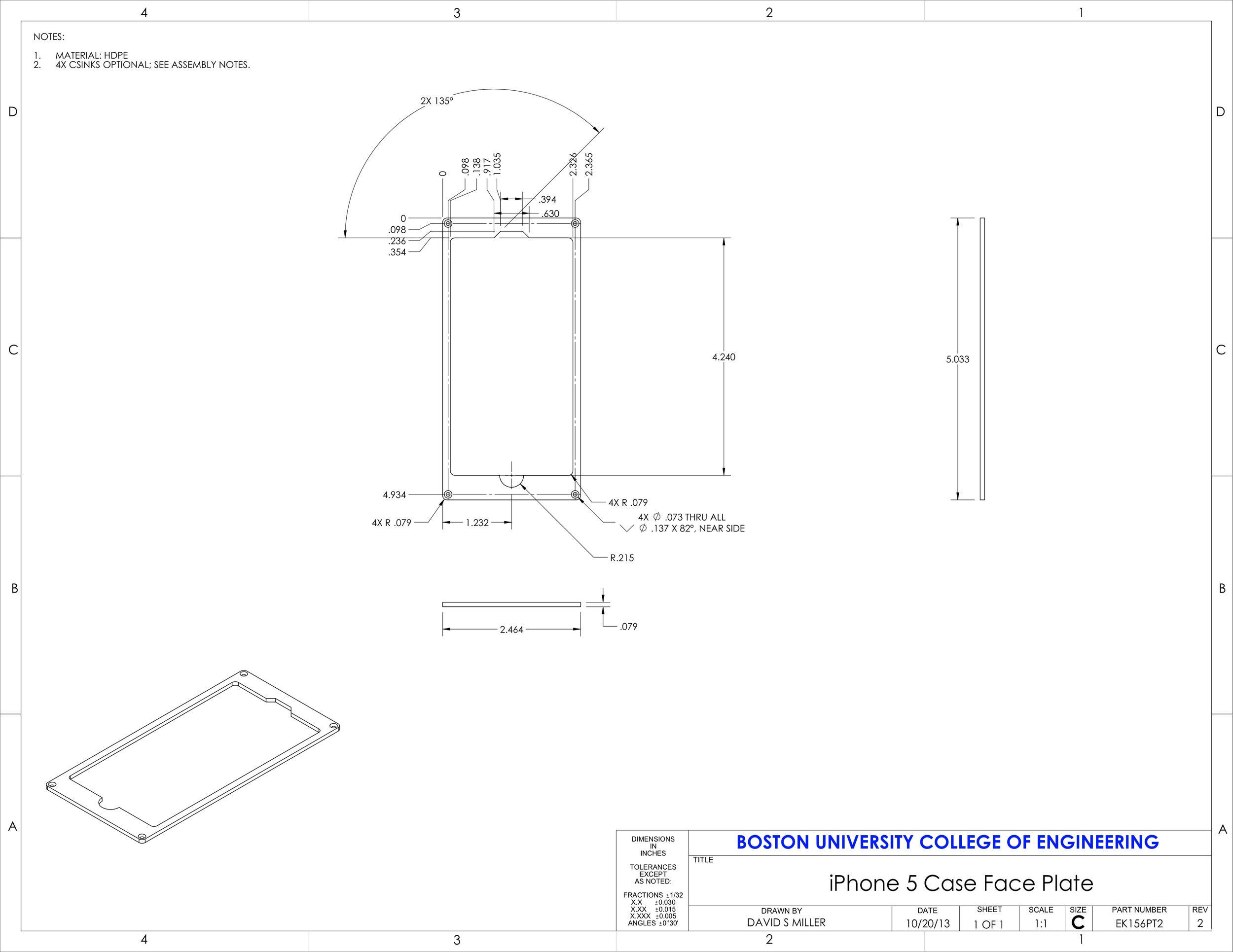

Design

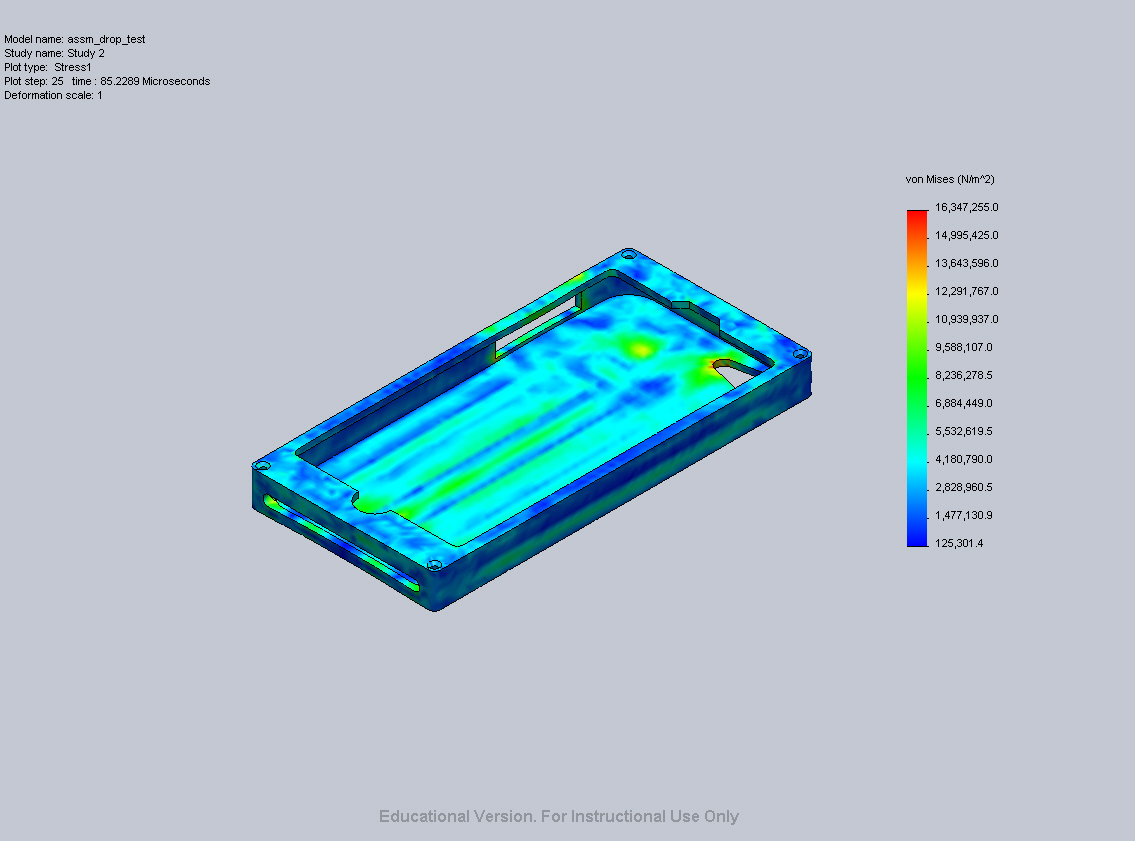

However, what resulted from most groups was a product similar to something that could be bought off the shelf, which they had paid more money in materials for than the commercial version. Our goal was to do the opposite: manufacture an iPhone case of comparable functionality to those on the market at a lower materials cost. Of course our cost analysis did not include the costs that would ordinarily be incurred by the machinist, however this was not in the scope of our project. Further iterations of the design will focus on simplifying manufacturability and improving ergonomics.