Pneumatic Brake Redesign

The term project for my Product Design class was novel - for the first time, a select few teams would be working with companies to improve their products. Our team was assigned to work with a local corporation on their pneumatic disc brake modules used in web tension control applications. I was team leader for this project.

Overview

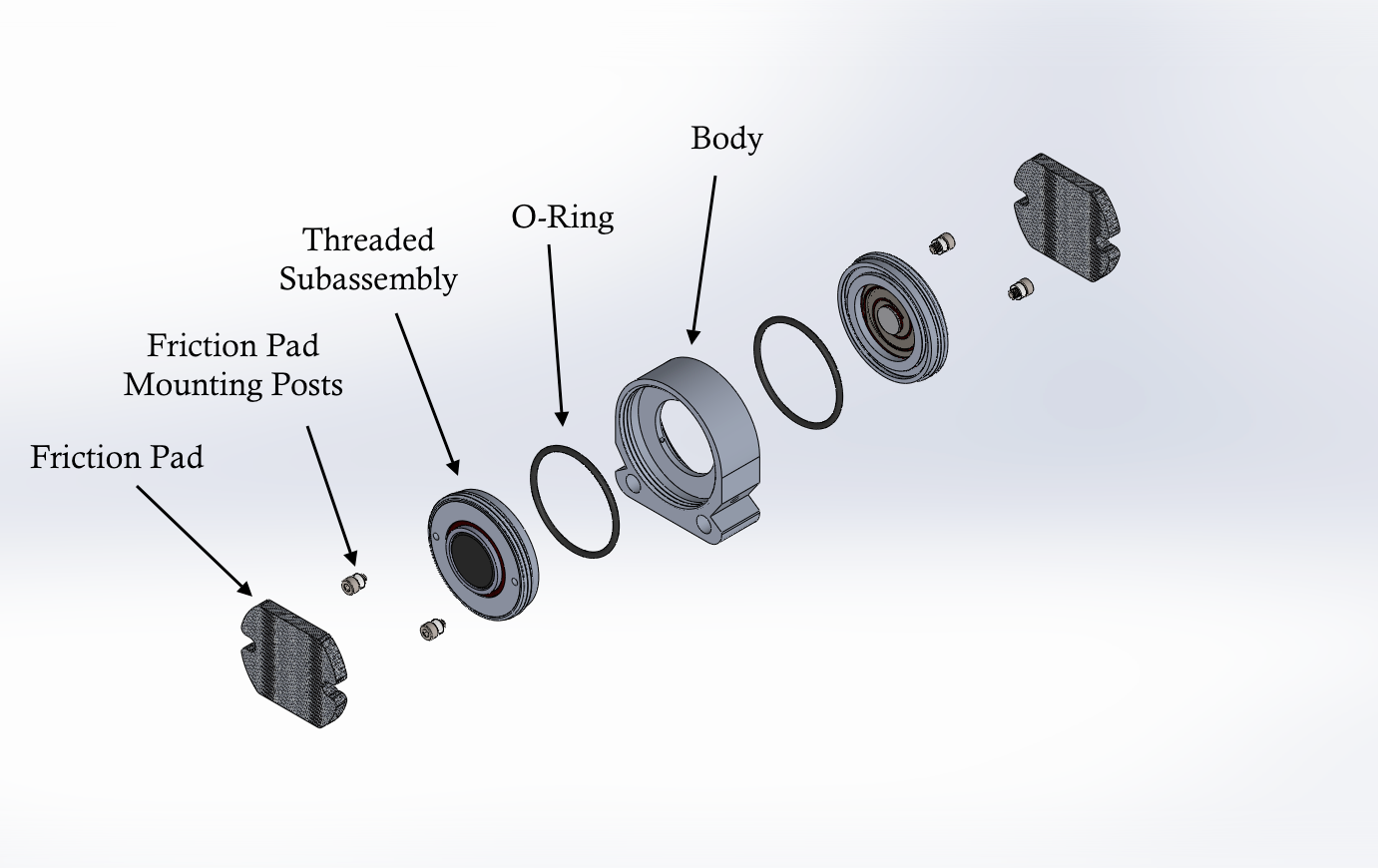

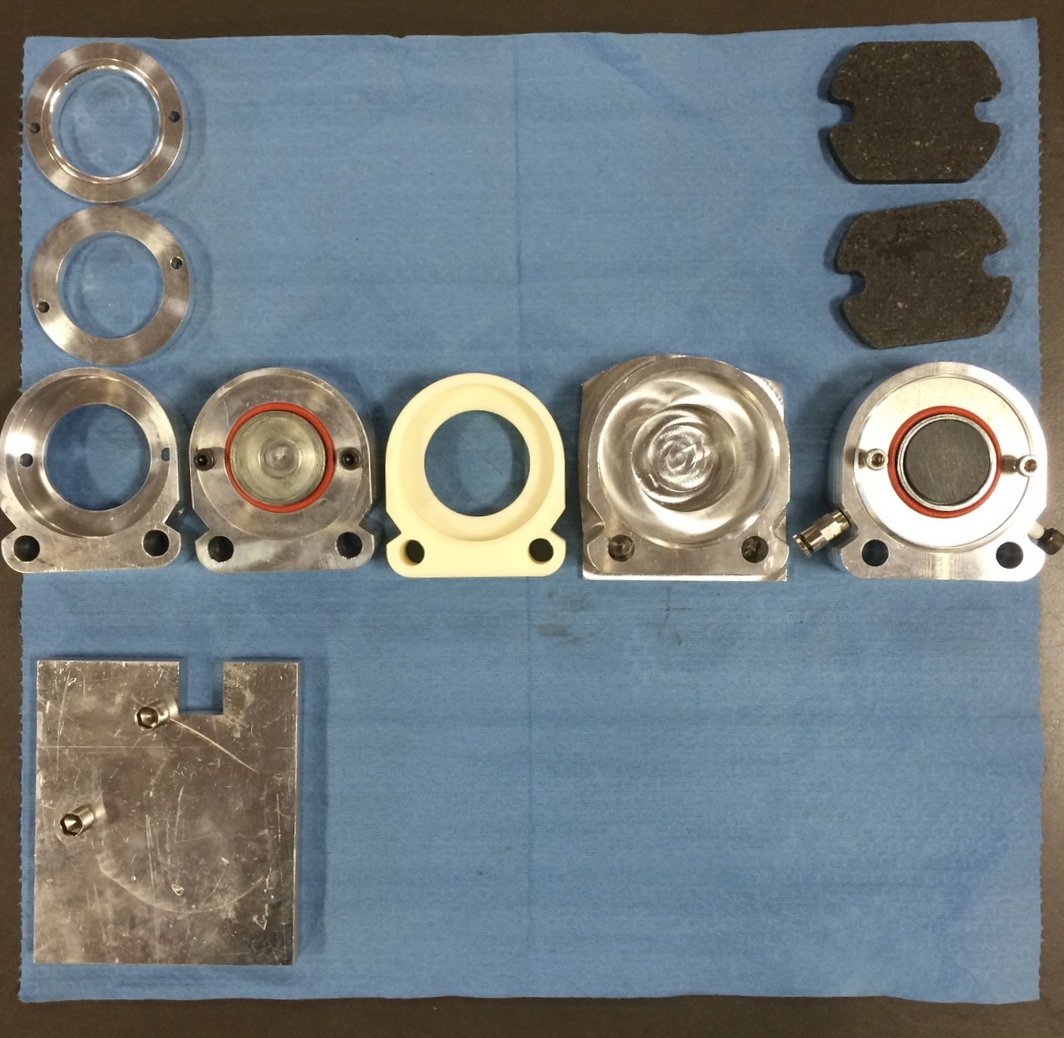

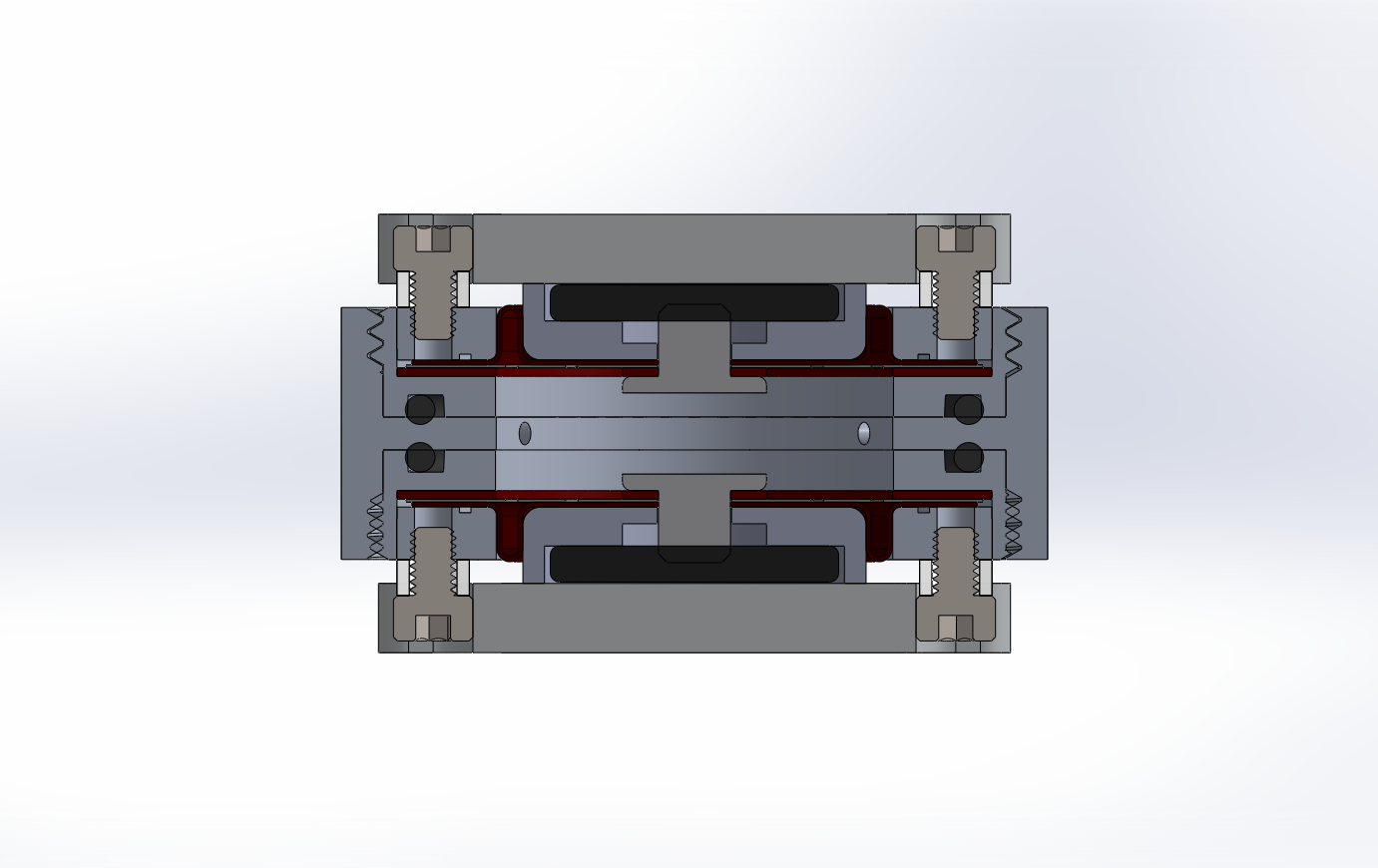

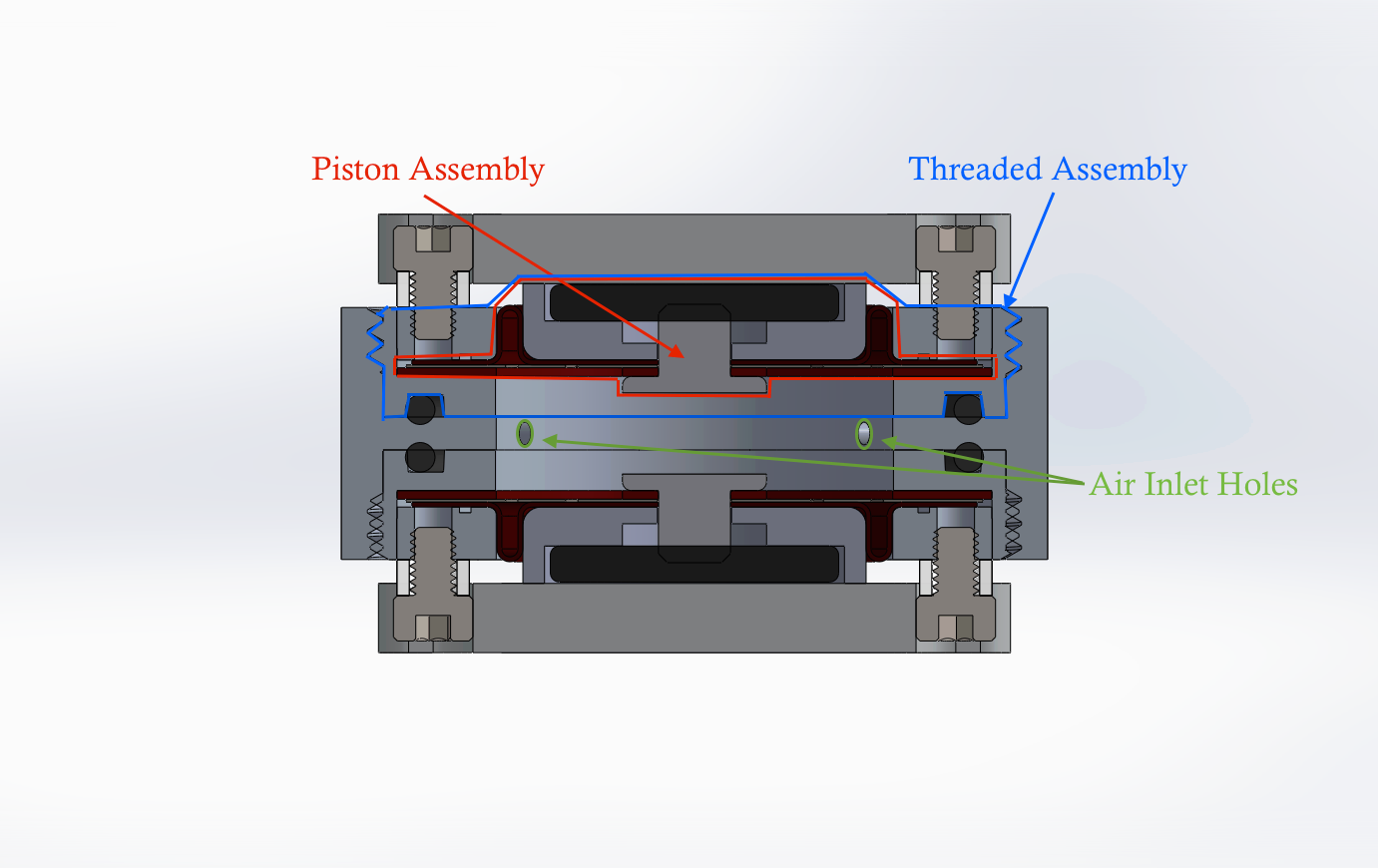

The Product

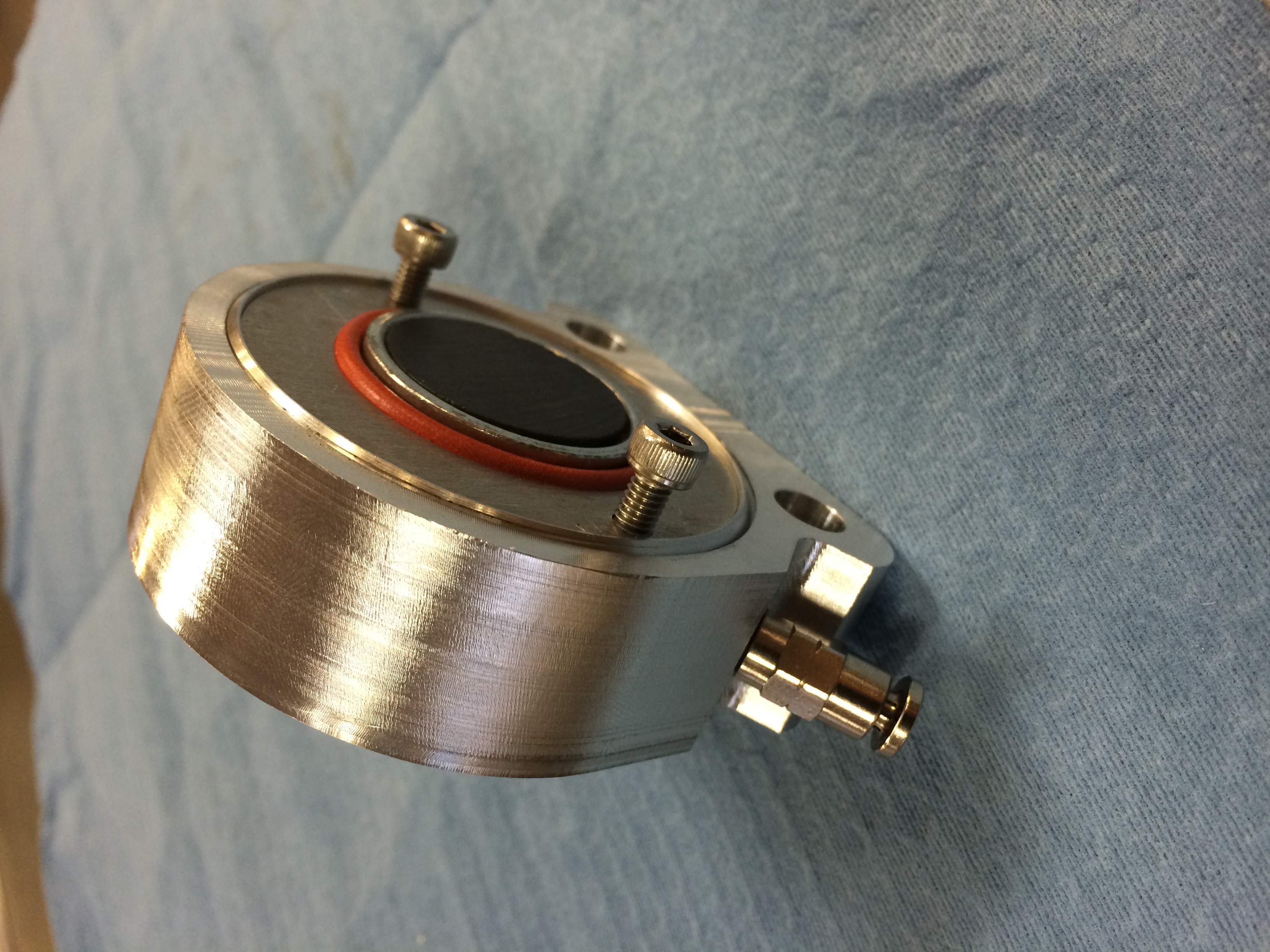

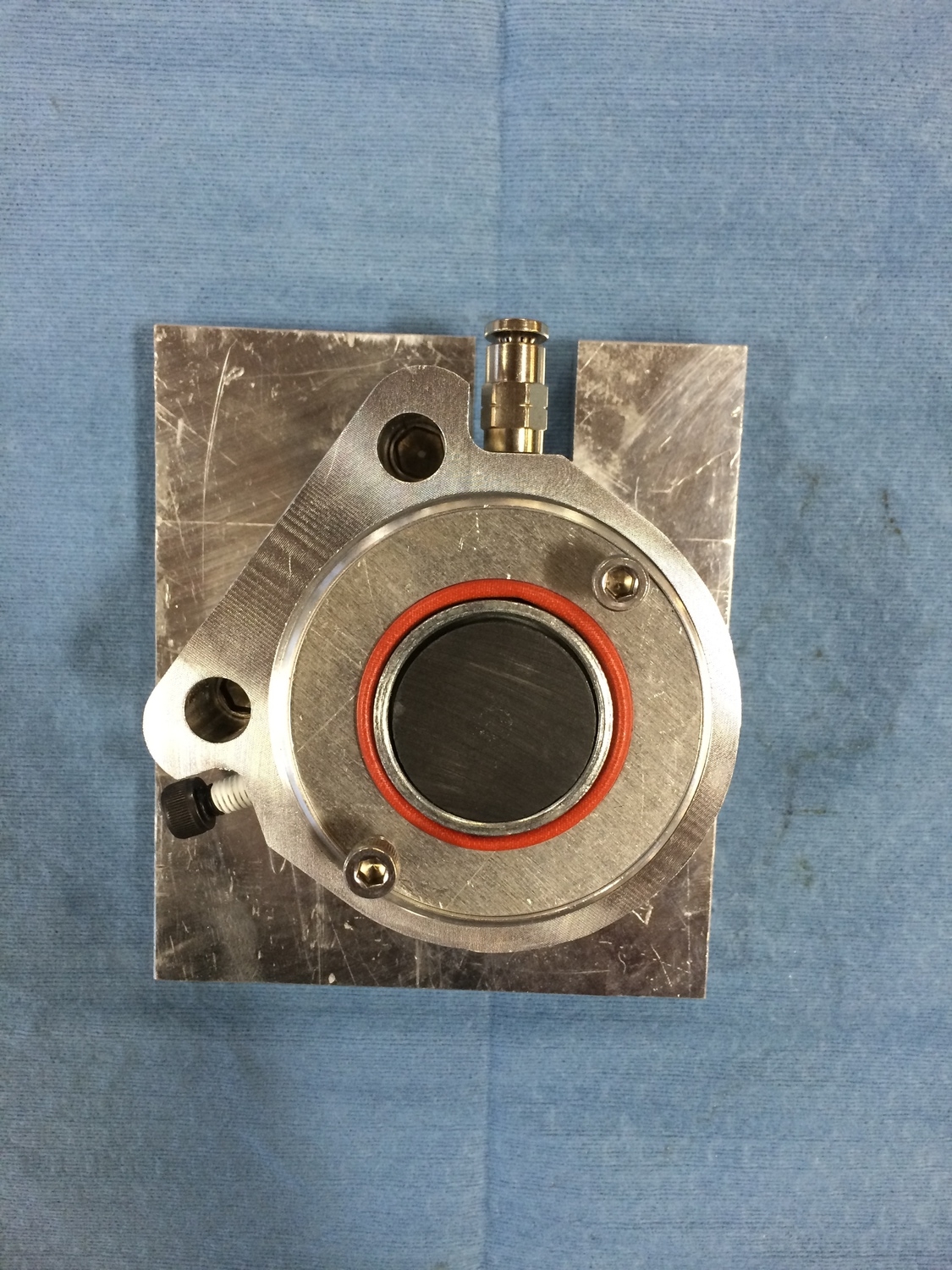

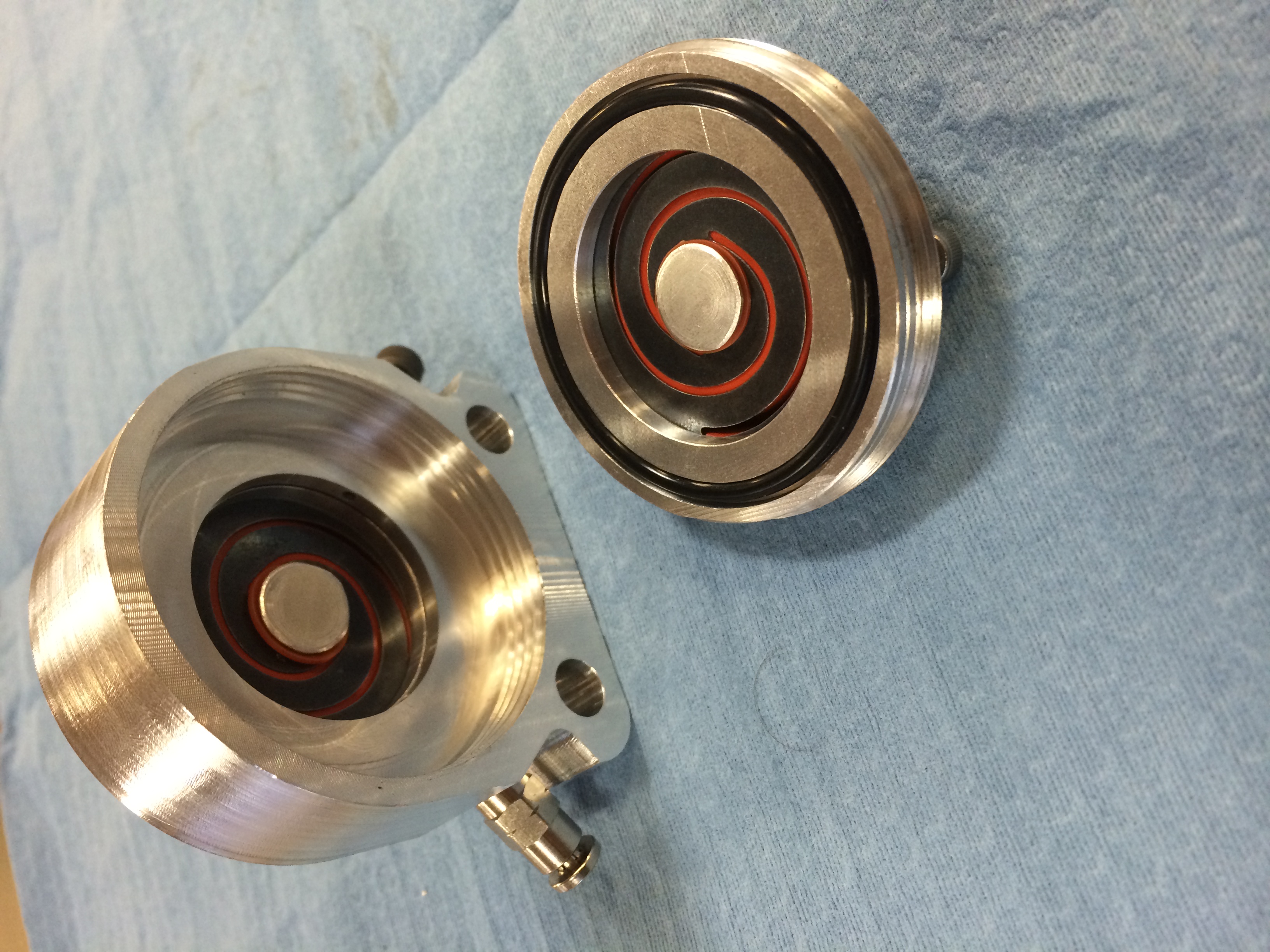

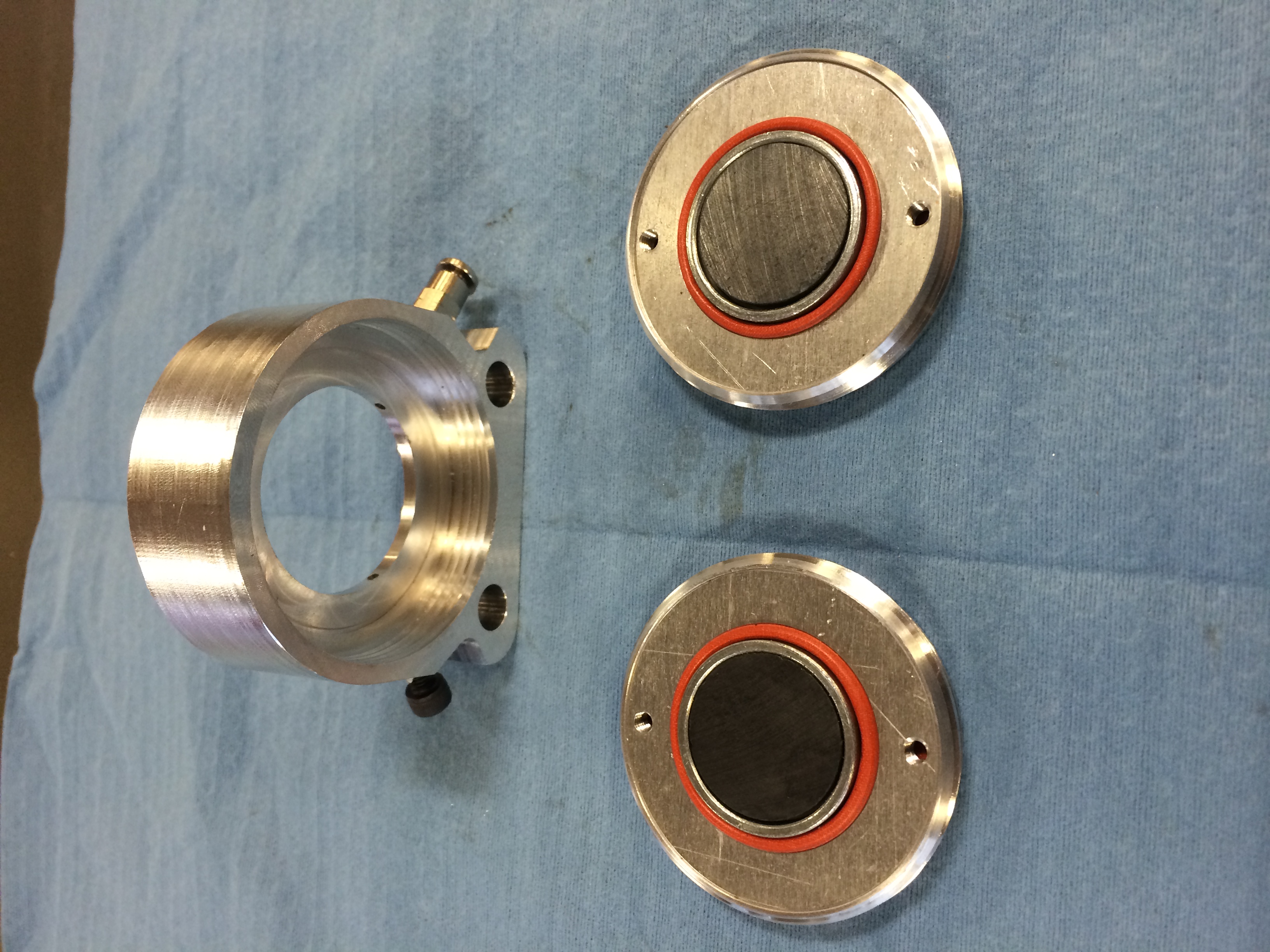

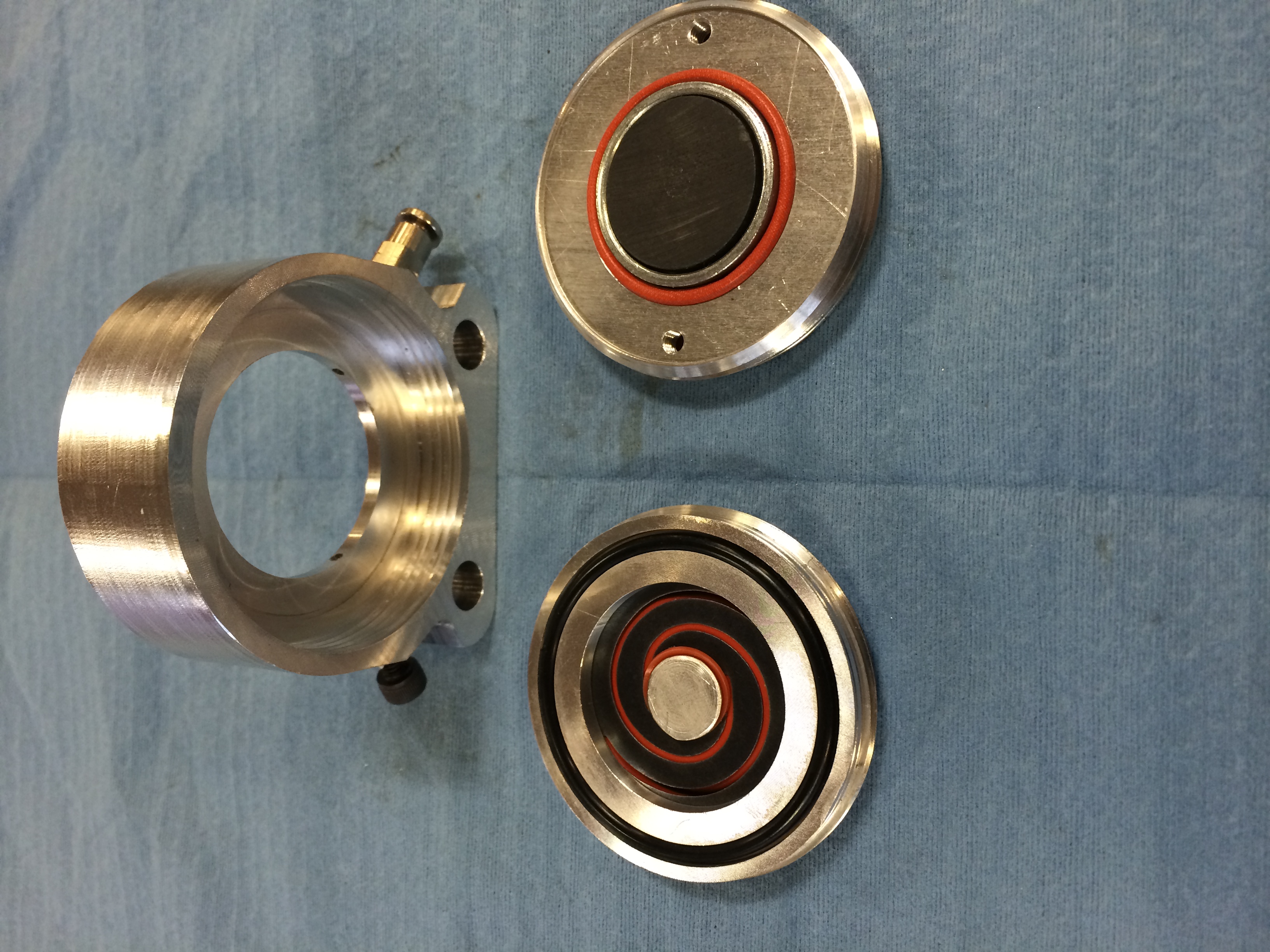

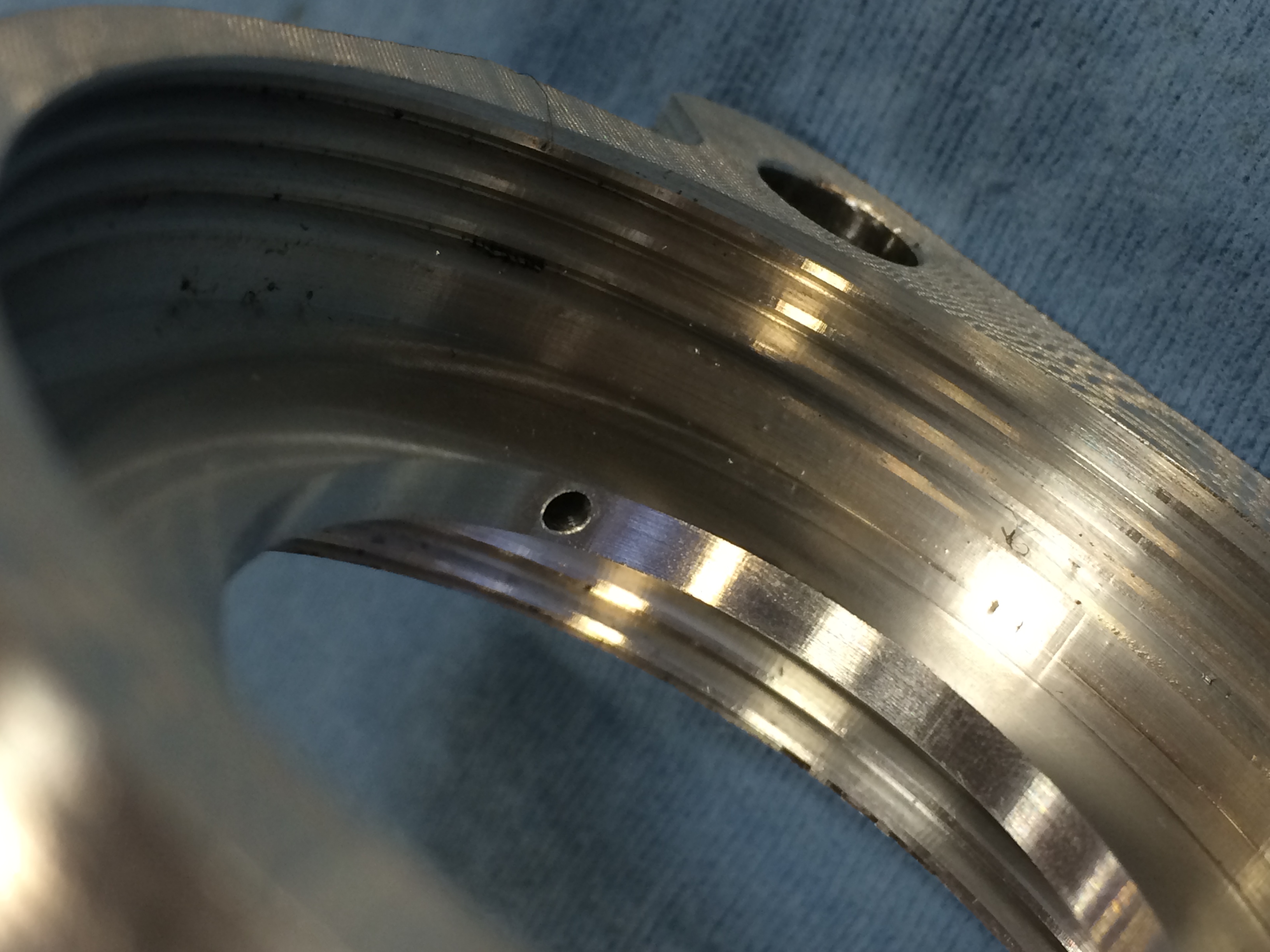

The customer makes web tension control products for facilities that process materials that come on rolls. Their disc brakes, load sensors, and control systems form a closed feedback loop to continuously monitor and adjust the tension in the web for proper web control. Our group focused on one family of their pneumatic disc brake modules. The brake modules in the family all use the same body, and have different configurations of piston assemblies and friction pads. One module has a piston assembly on one side; another module has piston assemblies on both sides. The third brake consists of two single sided brakes aligned and facing each other such that their pistons extend towards each other to apply force to a central disc. This is the opposite of the double sided brake where the pistons expand out to apply force to two connected discs.

The Problem

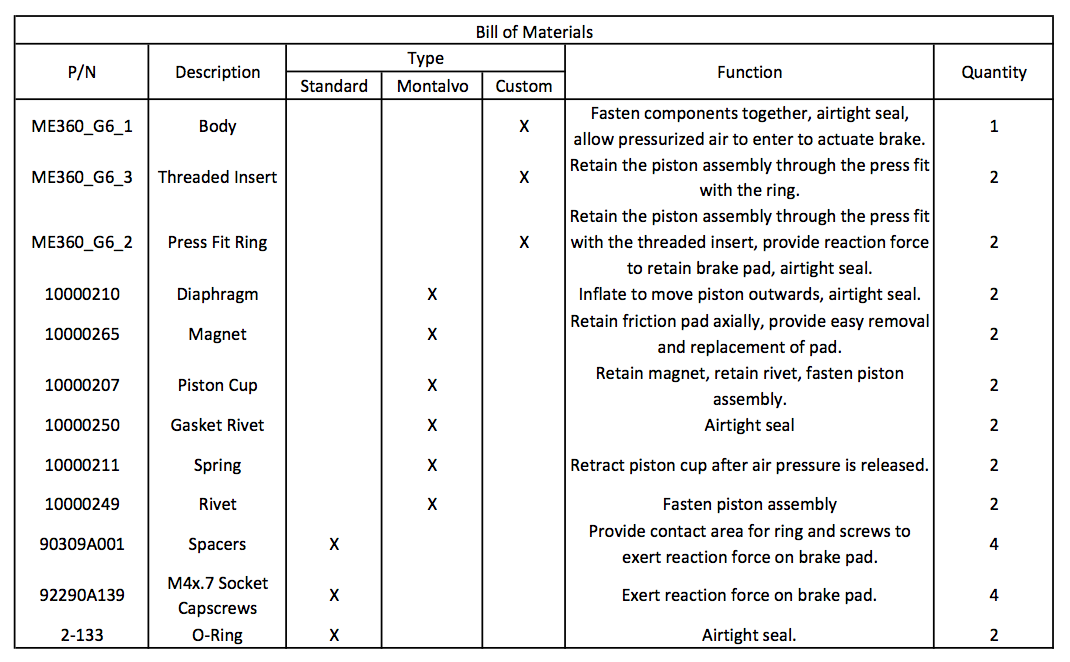

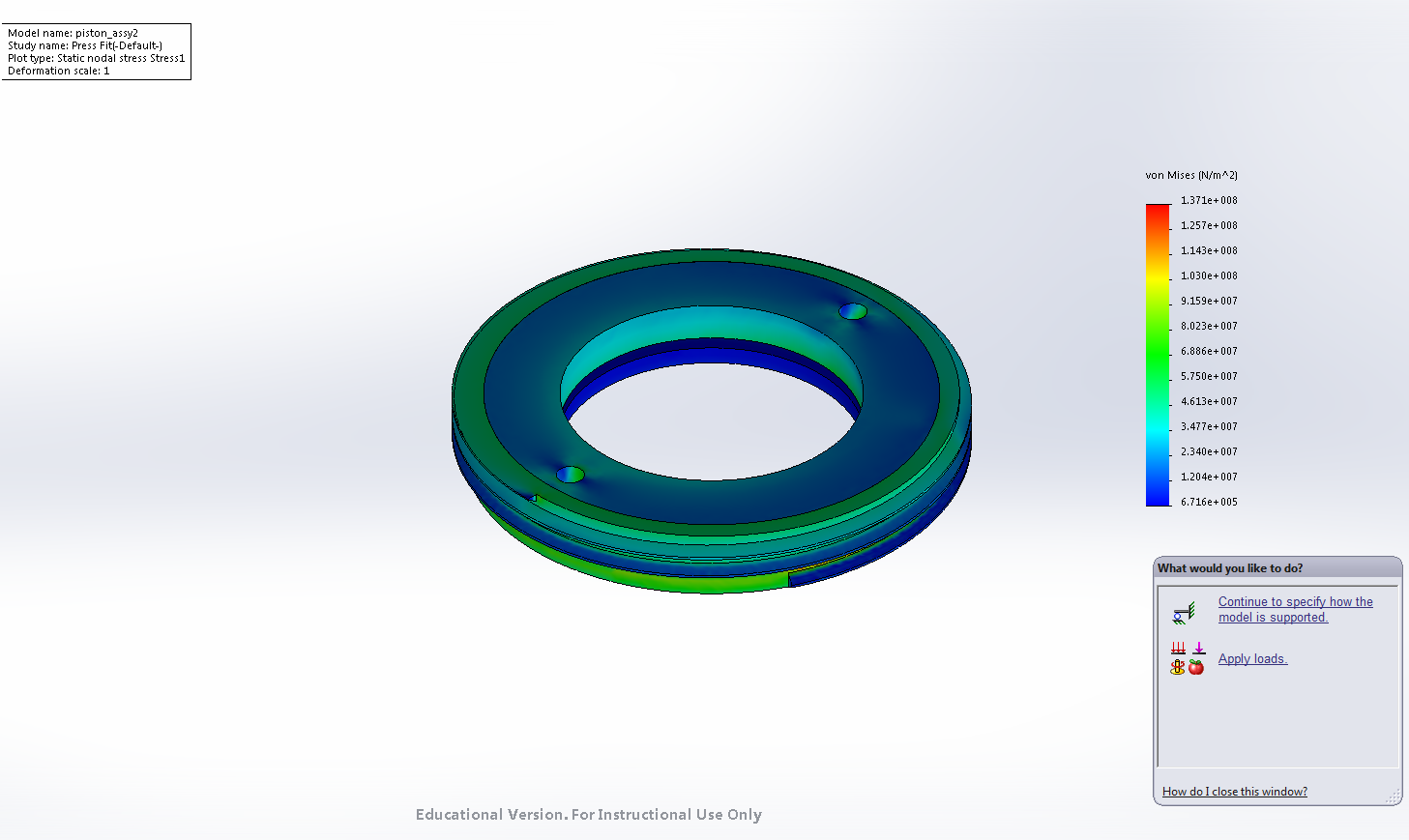

The customer's design relies on a press fit operation to create the airtight seal necessary for proper functioning of the brake. A ring is press fit around the piston assembly and into the body to assemble and seal the product. Therefore, the press fit has two functions: to assemble the product, and the create the airtight seal. This dual dependence is called function coupling. Function coupling is undesirable according to the principles of axiomatic design. In this case, function coupling was giving the customer trouble because of the fact that press fits are permanent. So in order to check the module for leaks, it had to be assembled. However, once it was assembled and a leak was discovered, it could not be disassembled to fix or diagnose the leak, and thus was discarded. Our goal was to address this problem in our design.

The Solution

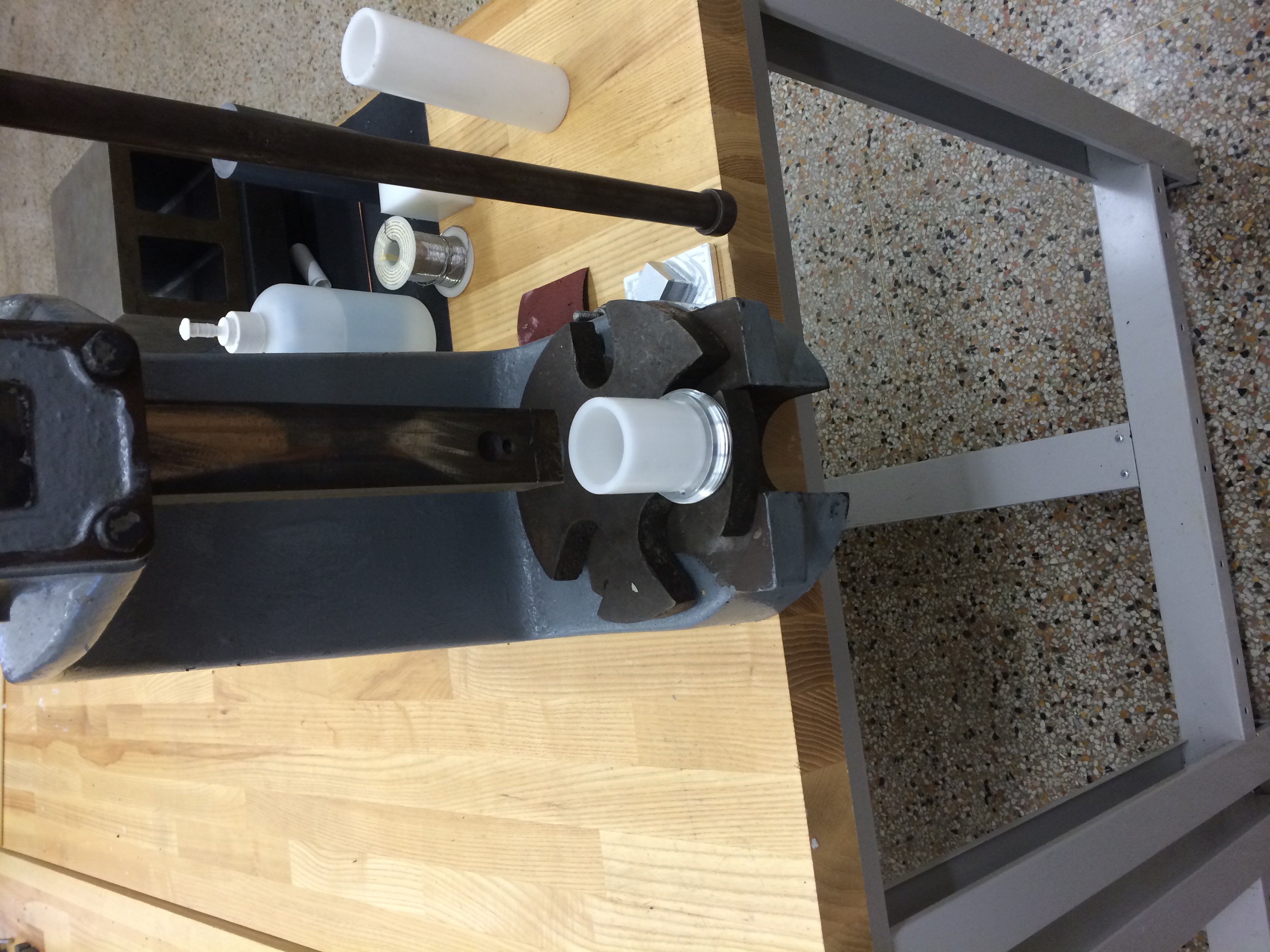

Our original plan was to do a failure mode analysis of the assembly to determine the origin and the cause of the leaks, then design and prototype an improved brake using that knowledge. However, a failure mode analysis, redesign, and construction of a prototype were not reasonable with such a short timeline. We decided instead to implement a turn-key solution by designing a fully compatible brake module which decoupled the functions of final assembly and airtight-ness.