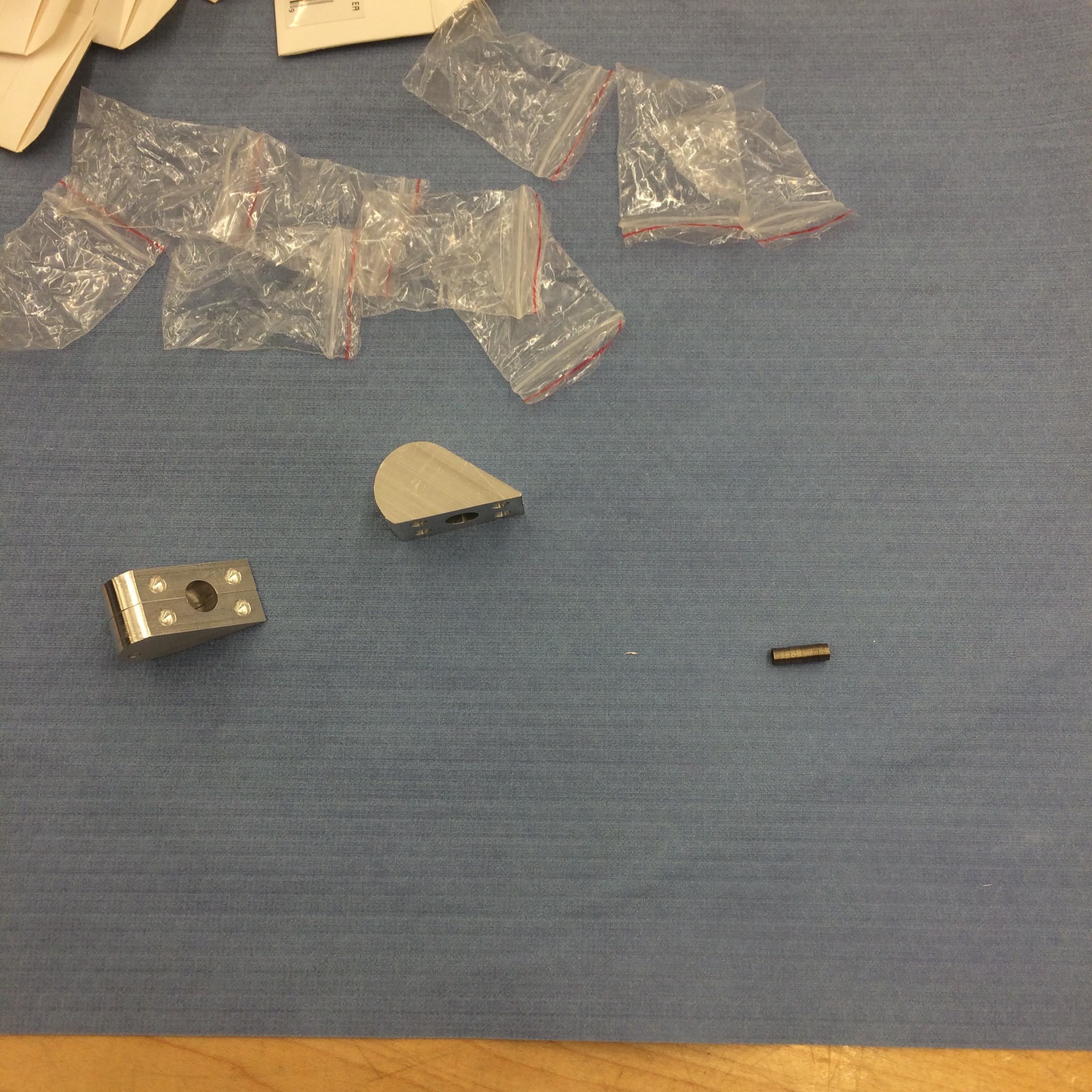

I did some work on the locket today. The first thing I did was I marked the sides of the magnets with a sharpie so I could distinguish between the N and S poles. To do this, I just stacked them all up and sharpie-d the tops one by one.

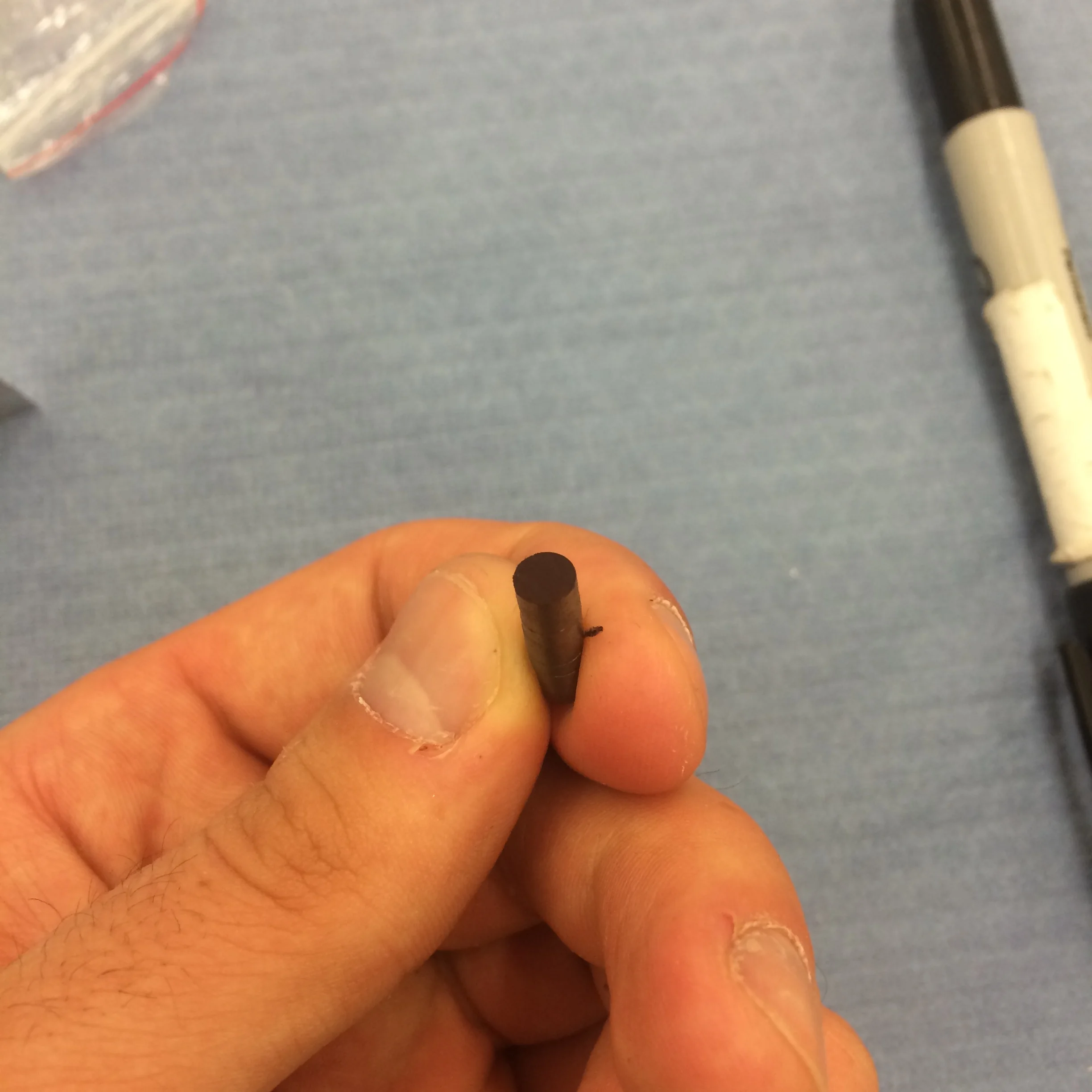

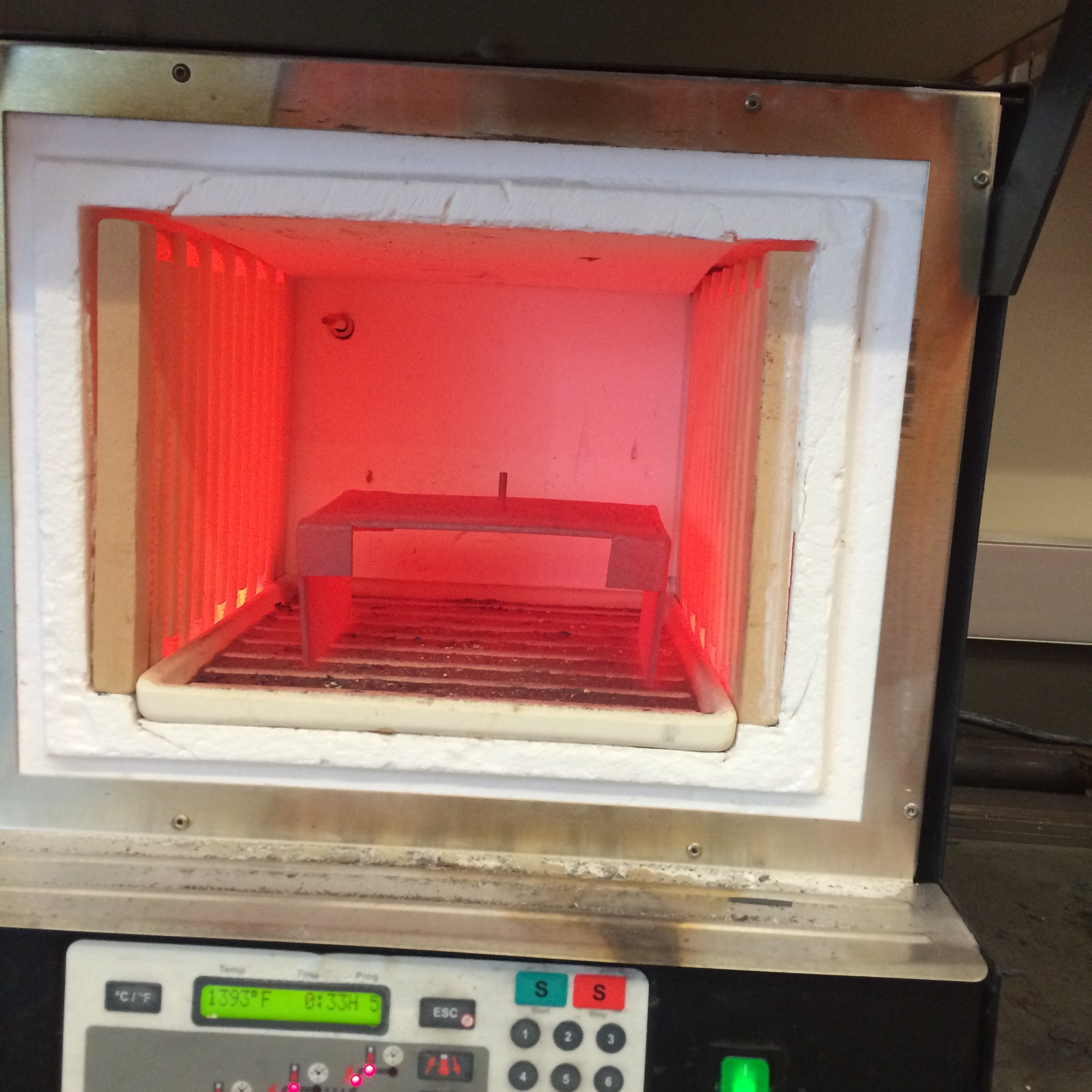

The next thing I did was I heat treated a pin I turned from O1 tool steel. I used the furnace to gradually heat it to 1450F and let it soak for 15min. I then quenched it in oil. The subsequent hardness test shows a hardness of almost C59 Rockwell. It started out as B96. The spec sheet says it can be hardened up to C64, but I am satisfied with C59. This just means I don't have to temper it back down again. Next I'm going to turn down the diameter a bit more with a tungsten-carbide tool and finish it with a grindstone on the lathe. I would use a cylindrical grinding method, but we don't really have that capability at the shop.